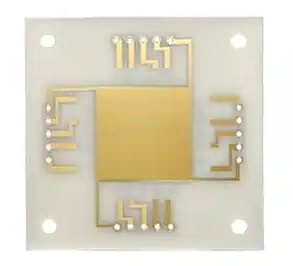

High-Temperature Ceramic PCB

Ceramic PCBs are engineered for extreme environments, delivering perfect performance in high temperature, high frequency, and critical applications. Utilizing materials like Alumina (Al₂O₃), Aluminum Nitride (AlN), and Beryllium Oxide (BeO), these boards outperform traditional FR4 or metal-core PCBs with superior thermal management, electrical stability, and mechanical durability. Fanway, as a specialist in ceramic PCB with rapid prototyping and scalable production.

Why Partner with Fanway?

Custom Engineering: Our R&D team designs tailored solutions to meet precise technical requirements.

Fast Prototyping: Our streamline development cycles with our one-stop prototyping services ensure quick validation.

Efficient Production: Advanced manufacturing enables cost effective and high volume output.

Technical Support: Our technical experts provide 24/7 assistance from design to mass production.

Features of Ceramic PCB

Property Specification

Operating Temperature -55°C to 1000°C (HTCC: up to 1600°C)

Thermal Conductivity Al₂O₃: 24–28 W/mK; AlN: 170–230 W/mK

Dielectric Constant 9.8–10.2 (@1MHz)

Breakdown Voltage >15 kV/mm

Coefficient of Thermal Expansion CTE 6–8 ppm/°C (aligned with semiconductor chips)

Applications

Power Electronics: High-voltage converters, EV battery systems

Aerospace: Avionics, satellite communication modules

Industrial: High-power LED arrays, laser diode drivers

Energy: Solar inverters, wind turbine controls

Shenzhen Fanway Technology Co., Ltd

Office Add: F601, Industrial Building of Hengtai, Tangkeng Road, Guantian Community Shiyan Street, Bao'an District, Shenzhen, Guangdong, China, 518108

Factory Add: F2, Building 3, The First Industrial Zone of Mingjinhai, Shiyan Street, Bao'an District, Shenzhen, Guangdong, China, 518108

E-mail: karena@fanwaypcba.com

Cell: +8615013656200

Copyright © 2025 Fanway | All Rights Reserved.