We understand that quality is the key in our PCB assembly services, to make sure every PCBA we build that meet the highest industry standards and customer expections, we implement a strict quality control system, our production plant has been certified by ISO 9001, ISO 13485 and IATF 16949, and our stuff were trained for IPC-A-610G Class II.

For Incoming Material Control

• All our components will be sourced from authorized agent and supply chain.

• Component authenticity verification through original manufacturer documentation

• We bake moisture-sensitive component at 125°C for 24 hours .

• Solder paste viscosity testing and stencil inspection

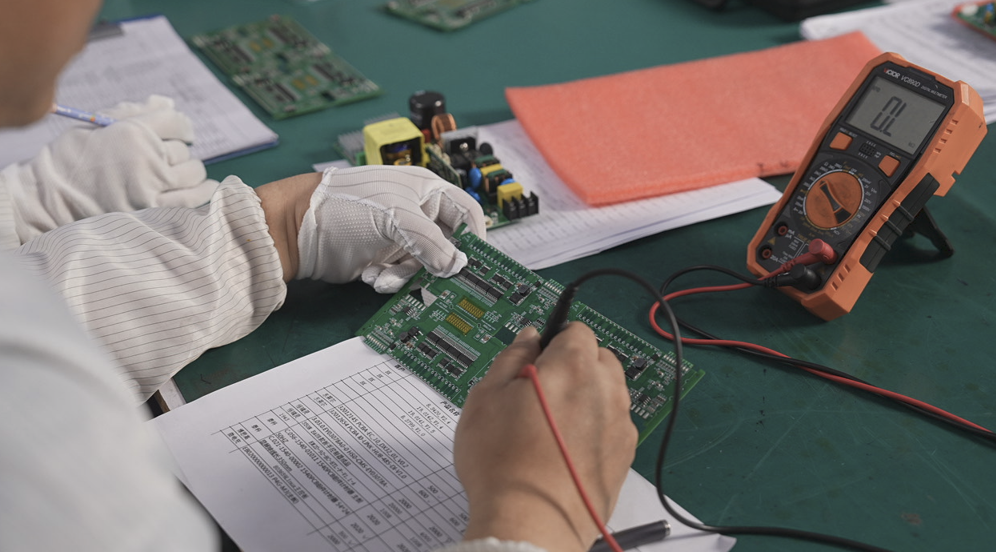

In Process Quality Checks

• We have solder paste inspection to check the paste quality.

• Every PCBA will be inspected by automated optical inspection for component placement accuracy.

• Before every mass production, we have first-article inspection.

• Workers real-time monitoring of reflow profiles.

Final Quality Control

• 100% electrical testing with custom test fixtures

• X-ray inspection for BGA and QFN components

• Functional testing under simulated operating conditions

• Microsection analysis for critical assemblies

Shenzhen Fanway Technology Co., Ltd

Office Add: F601, Industrial Building of Hengtai, Tangkeng Road, Guantian Community Shiyan Street, Bao'an District, Shenzhen, Guangdong, China, 518108

Factory Add: F2, Building 3, The First Industrial Zone of Mingjinhai, Shiyan Street, Bao'an District, Shenzhen, Guangdong, China, 518108

E-mail: karena@fanwaypcba.com

Cell: +8615013656200

Copyright © 2025 Fanway | All Rights Reserved.