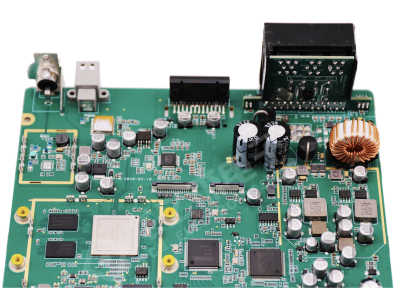

THT PCB Assembly

Through Hole Technology (THT) PCB assembly provides durable mechanical connections for components requires high strength and reliability. At Fanway, we deliver precision THT assembly services using both manual and automated ways.

Why Choose Fanway?

12+ Years of Expertise

Rich experience in manual and automated THT assembly.

Our process compliance with IPC-A-610 and ISO 9001:2015 standards.

High Precision

Automated insertion machines and wave soldering systems enable accuracy.

Our skilled technicians handle complex and low volume manual assembly.

Quality Control

Inspections include AOI, X-ray, visual checks, and functional testing.

Flexible Production

We support for prototypes, small batches, and high volume orders with fast turnaround.

Production Process of THT Assembly

1. Component Insertion

We insert component, such as Axial, radial, DIP, and connector into PCB holes via automated systems or manual techniques.

2. Wave Soldering

Using advanced wave soldering equipment for forming durable solder joints.

3. Inspection & Testing

Use AOI and X-ray to inspect solder quality.

Capabilities

Component Types: Axial, radial, DIP, connectors, custom through-hole parts.

Equipment: Automated insertion machines, wave soldering systems, manual stations.

Quality Assurance: AOI, X-ray, visual inspection, functional testing.

Certifications: IPC-A-610, ISO 9001:2015, RoHS, REACH.