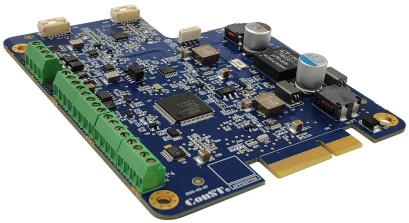

SMT PCB Assembly

Your Reliable Partner for Electronics Manufacturing in China

Fanway is a manufacturer with over 12 years of experience in OEM/ODM PCB and PCBA production. Our surface mount technology (SMT) processes meet the highest industry standards, including ISO 9001, IPC-610 Class 2, and UL certifications. We deliver high quality and reliability PCBA service from prototyping to full-scale production.

Why Choose Fanway?

✅ Quality Assurance

Inspections: Solder Paste Inspection (SPI), Automated Optical Inspection (AOI), X-ray, functional testing, and visual checks. Precision component placement and soldering ensure durable, high-performance PCBs.

✅ Scalable Solutions

Prototyping and small batches for R&D and startups.

High-volume production for large-scale manufacturing needs.

✅ Advanced Technology

High-speed SMT equipment and skilled engineers ensure efficient, accurate production.

Production Process

1. Solder Paste Printing

Precise application of solder paste using advanced stencils.

2. Component Placement

High-speed machines place components (01005, BGA, QFN, LGA, etc.) with ±0.025mm accuracy.

3. Reflow Soldering

Controlled ovens create reliable solder joints.

4. Inspection & Testing

SPI, AOI, X-ray, and flying probe testing eliminate defects.

5. Final Assembly

Conformal coating, box-build assembly, and secure global delivery.

Technical Capabilities

Production Capacity: 8 SMT lines, 10 million placements per line daily.

Component Support: 01005, BGA, QFN, DFN, LQFP, LFCSP, WLCSP, SOIC, UBGA, Power SO, LGA.

Quality Control: SPI, AOI, X-ray, flying probe, functional testing.

Certifications: ISO 9001, IPC-A-610 Class 2, UL, RoHS, REACH.